Coatings company PPG has launched a new marine coating, described as a breakthrough approach to help shipowners lower power consumption and carbon emissions and meet demands for higher performance with no adverse impact on the marine environment.

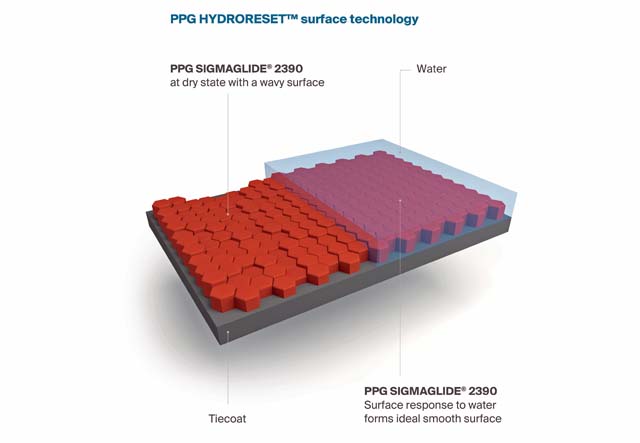

PPG Sigmaglide 2390 marine coating is a biocide-free fouling release coating based on PPG’s Hydroreset technology, which modifies the coating when it is immersed in water to create a super-smooth, almost friction-free surface that marine organisms do not recognise and cannot adhere to.

Based on third-party evidence following ISO 19030 and ITTC standards, the coating enables vessels to maintain a clean hull and reduce drag, achieving power savings of up to 20%, a speed loss performance of less than 1%, and up to 35% reduction in CO2 emissions in comparison to traditional antifouling coatings. Actual performance will depend on ship model and operating conditions. PPG Sigmaglide 2390 coating is said to help owners and operators to meet targets for reduction of greenhouse gas emissions under the IMO energy efficiency (EEXI and EEDI) and carbon intensity (CII) requirements.

Jan Willem Tegelaar, PPG global platform director, Marine Coatings, said: “PPG Sigmaglide 2390 coating is a unique formulation that paves the way for ship owners and operators to improve efficiency and reduce CO2 emissions. The speed loss performance of less than 1% helps ships operate at an average one knot higher speed while remaining CII compliant.”

The fouling control performance of PPG Sigmaglide 2390 is achieved with no release of biocides into the oceans. PPG Sigmaglide 2390 coating is suitable for electrostatic application, which provides high transfer efficiency, leading to lower paint consumption. In service, the coating can deliver up to 150 days of idle performance and an extended lifetime of more than 10 years with minimal maintenance requirements. These benefits, combined with the power savings, provide what is believed to be an industry-leading return on investment for shipowners.