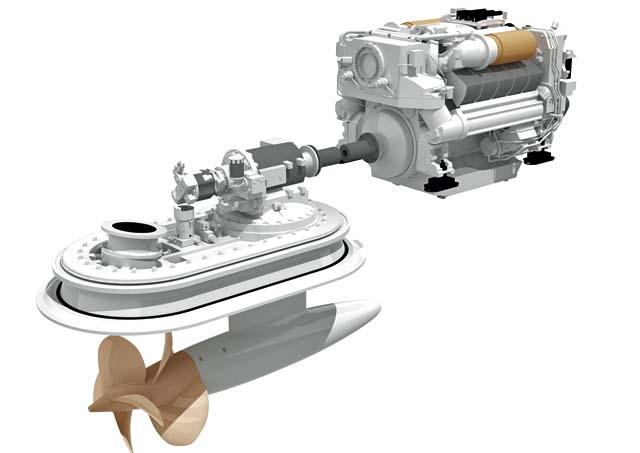

Rolls-Royce Power Systems and ZF have introduced a new podded drive, as part of the mtu portfolio aimed at the yacht and workboat market.

The long-standing partnership between the two companies is expanding to include pod propulsion packages in the power range up to 1,250kW (1,700 bhp), and later also up to 1,470kW (2,000 bhp), based on mtu Series 2000 engines and ZF’s POD 4600.

Denise Kurtulus, VP Global Marine, Rolls-Royce business unit Power Systems, said: “Our strategic goal is to offer our customers integrated, highly efficient solutions in the yacht market – from bridge to propeller. This includes our bridge solutions, automation and crew assistance systems, mtu engines, mtu hybrid systems, and now pod drives. We offer this integrated solution to provide a better yachting experience with easier maneuverability and space and efficiency gains. Propulsion efficiency can be increased by up to 15% with the mtu-ZF combined solution, significantly reducing the carbon footprint. Compared to conventional fixed propeller drives, the yacht’s manoeuvrability can be significantly improved.”

Federico Decio, ZF Head of Business Unit Marine and Special Driveline Technology, added: “We know that shipbuilders around the world count on ZF to bring performance, efficiency, and reliability to a growing variety of vessels. And that’s exactly what we have achieved with the new ZF POD Propulsion 4600 System.”

The new systems will be offered for series-production yachts up to around 30m in length with a top speed of up to 32 knots, and for workboats such as crew transfer vessels. New projects are being developed in close cooperation between Rolls-Royce with its Italian-based Yacht Competence Center, ZF and yacht manufacturers. In the future, Rolls-Royce will supply the complete propulsion package to the customer.

At the same time, Rolls-Royce has approved the mtu Series 2000 and 4000 yacht engines for EN15940 synthetic diesel fuels, including BtL (Biomass to Liquid), HVO (Hydrotreated Vegetable Oil) and PtL (Power to Liquid) such as e-diesel. All of them can replace conventional fossil-derived diesel fuel in these engines without any adjustments.

The benefits of HVO are clean combustion with a reduction in particulate emissions of 40% or more, NOx emissions of up to 8%, and (depending on the production process and feedstock) CO2 emissions of up to 90% well-to-wake.