Mitsui OSK Lines (MOL) has invested in US company 13 Mari, a developer of ripple-shaped ‘Flowsmart’ elements that are retrofitted to ships’ hulls, with the goal of developing and providing new solutions for GHG emission reduction.

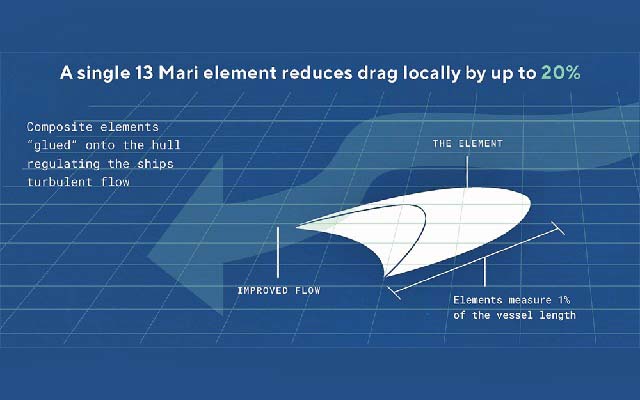

The ripple-shaped Flowsmart element uses technology which has been incorporated into the shape of aircraft wings and automobile aerodynamics, based on the concept of controlling the flow of water near the hull to reduce drag and enhance the original performance of the vessel. The company aims to improve the fuel efficiency of vessels and achieve stable navigation.

The Flowsmart elements are expected to reduce GHG and fuel consumption by 3%-7% on vessels retrofitted with 10 to 20 of the elements, and more when combined with currently available energy-saving devices such as wind propulsion systems and various types of fins.

In addition, because all kinds of ships, both newbuildings and in-service vessels, can be retrofitted with these elements, and retrofitting does not require a large capital investment or retrofitting work, they can be used in various fields of the shipping industry, such as dry bulk, energy, and product transport, representing an environmental solution that can be taken now. They may prove especially effective in the small and medium-sized ship sector, where it has been difficult to introduce wind propulsion systems due to the limited device and equipment layout space on board, and in the dry bulk field, where the introduction of next-generation fuels has been limited due to restrictions on the design and development of new ship types and ports of call. MOL seeks to promote GHG emission reductions and build momentum in the entire maritime industry for the introduction of new technologies in these fields, by playing a role in the development and introduction of new technologies as a first mover.

Image: Conceptual diagram of a composite element (source: MOL/13 Mari)