Fujian Mawei Shipbuilding and Xiamen Shipbuilding Industry in China have ordered four MAN 10L32/44CR medium speed main engines in connection with the construction of four 41,000 dwt oil-and-chemical tankers for German Tanker Shipping (GTS).

The construction of the 199m newbuildings designed by FKAB of Sewden is set to start at Xiamen Shipbuilding with delivery scheduled from mid-2025 onward. The order includes options for an additional two vessels.

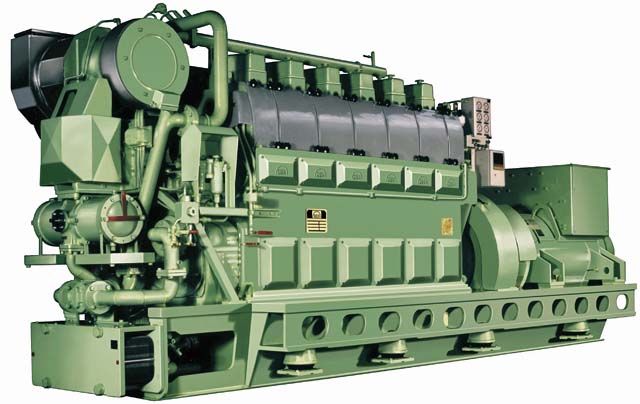

Each main engine will have a power output of 600kW per cylinder and comes integrated with MAN Energy Solutions’ proprietary LP-SCR (Low-Pressure Selective Catalytic Reduction) system that delivers NOx-reduction rates of up to 90% in fulfilling the latest IMO environmental requirements. Each engine will drive a MAN Alpha VBS1260 CP propeller via a Flender GUCK-1560 gearbox.

Each vessel will feature MAN auxiliary engines in the form of two 8L23/30H Mk2 (at 900 rpm) and one 6L23/30H Mk2 (at 720 rpm) gensets. MAN Energy Solutions licensee CSSC Marine Power (CMP) will build these engines in China.

GTS Executive Management stated that it was very proud to continue its newbuild investment program, especially during the company’s 25th anniversary year, with its long and loyal partner, MAN Energy Solutions.

Lex Nijsen – VP Marine Europe and Americas, MAN Energy Solutions, said: “This entire project is testimony to the excellent, decades-long cooperation between GTS and MAN Energy Solutions. It’s a notable feather in our cap to have been selected as propulsion-system supplier for these ice-classed newbuilds.”

Christian Kamm, Sales Manager Europe Marine, MAN Augsburg, said: “The MAN 32/44CR engine maintains high efficiency at all times and there is no fuel penalty or de-rating when operating the SCR system, especially with HFO. This is in great part due to the lower temperature that MAN SCR solutions operate at and that meet the highest emission standards.”

MAN common-rail engines are capable of burning conventional fuels like HFO, MDO and MGO, as well as sustainable fuels like biodiesel (HVO and/or FAME). They are designed to be ready for retrofit to methanol operation as green fuel should that be desired at a later stage. The 32/44CR’s SaCoS 5000 engine automation system enables it to fulfil cyber security requirements and facilitates remote technical support.

Colin Peesel, Head of Sales and Promotion, Germany, MAN Energy Solutions, added: “The combination of the MAN 10L32/44CR main engine and MAN Alpha CP propeller – including the intelligent Alphatronic 3000 propulsion control system – will deliver a reliable, efficient and flexible solution, running the vessels at their optimal loadpoint in order to align with the all-important Energy Efficiency Design Index.”

Jens Munch – Sales Manager, MAN Alpha Frederikshavn, said: “In this particular order, we are using our newest technology by fitting the ships with water-lubricated stern tubes. In doing so, we are ensuring that there is no ‘oil-to-water interface’, eliminating any possibility of oil leaks and boosting the owner’s green profile. Such stern tubes are one of the biggest eco-trends that we foresee in the market and we have proven technology available based on our great experience with naval vessels where this solution has been used for many years.”

GTS is a Bremen-based shipping company with a fleet consisting of 14 modern oil-product tankers. All built in Germany, nine vessels sail under the German flag and five under that of the Seychelles; GTS manages all its own tankers.

Image: 32/44 medium speed engine (credit: MAN ES)