Dutch company Blue Wasp Marine has been working with Technical University Delft (TU Delft) and the Sea Axe Fund to assess the potential of a small modification to the Flettner rotor wind assistance device.

Using its in-house developed Pelican software, Blue Wasp studied the effects of adding a flap to the rotor and achieved improved performance and significant reductions in both emissions and fuel consumption. In the circumstances covered by the trials, inclusion of the flap was shown to increase performance by some 35%. The fuel savings were increased from 6.8% to 9.2% when using one rotor (which is an increase of about 35%), or from 10% to 13.3% when using two rotors (which is an increase of about 33%).

Giovanni Bordogna, founding partner and aerodynamics specialist, Blue Wasp Marine, said: “These tests demonstrate the significant potential of wind-assisted propulsion to support the maritime industry meet the challenges it is currently facing. Our results demonstrate how a small adjustment to a Flettner rotor can have a big impact, making shipping operations considerably cleaner and more cost-effective.”

The potential of a Flettner rotor to reduce a vessel’s fuel consumption is already well established. However, the rotor is known to have a relatively large drag, which reduces its aerodynamic efficiency, particularly when sailing upwind. TU Delft and Sea Axe Fund hit upon the idea of incorporating a flap to the rotor to fix the flow separation point, thereby altering the lift and drag forces created. To test this, they approached Blue Wasp Marine. To collect the required data on Flettner rotor aerodynamics, Blue Wasp conducted tests at the wind tunnel at the Politecnico di Milano in Italy. This information was then combined with the in-built force models of Blue Wasp’s Pelican software.

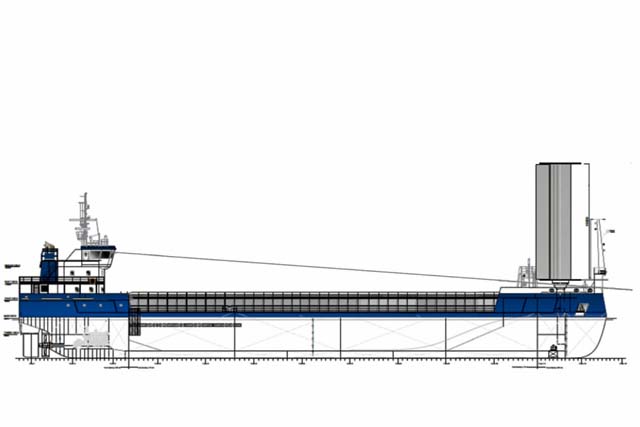

Next, Blue Wasp established a series of controls to ensure the accuracy of the experiment. Pelican was to assess the two vessels, one with a Flettner rotor alone and one with rotor and flap, sailing at the same speed, in the same conditions, on the same route. The company selected to perform the study with a Damen Combi Freighter 5000. This 86m x 15.3m vessel was considered a good representative of its type and indicates the effects of the Flettner rotor and flap on a nearshore cargo vessel.

Factors included in the tests were the thrust of the Flettner rotor, wind, resistance in both waves and calm water and resistance resulting from leeway, heeling and rudder operation. The performance of the two vessels was considered over the same North Sea route, between Rotterdam, the Netherlands and Trondheim, Norway.

The tests demonstrated that the addition of the flap delivered a significant increase in aerodynamic thrust, increasing the vessel’s operating profile. The vessel equipped with the Flettner rotor and flap has a tacking angle in the region of 15 degrees smaller than the one with only the rotor. This allows the vessel to sail significantly closer to the wind, vastly improving efficiency of performance upwind.

Though not a part of the study, the results established that, in most positions, the flap’s decreases of lift and drag resulted in reduced downwash and less accelerated flow in the rotor wake. This results in a relatively smaller aerodynamic sideforce, requiring smaller heeling, leeway, and rudder angles to reach sailing equilibrium. This means that the vessel with the rotor and flap can operate at higher wind speeds.

Albert Rijkens of TU Delft said: “Wind-assisted ship propulsion has found renewed interests from the shipping industry to meet the global climate goals and it will play a vital role to lower emissions, especially for large ocean-going vessels. This research demonstrates how small modifications to well-known rotor systems can already make a big difference in the propulsion efficiency of wind-assisted ships. Delft University of Technology will continue to intensify its research in this area by making wind-assisted ship propulsion one of its spearheads of maritime research for the coming years.”

Bordogna concluded: “This case study highlights the effectiveness of Pelican. By conducting studies such as this, we can investigate the potential of various approaches to wind-assisted propulsion prior to implementation, de-risking wind investment for ship owners and operators and helping to decarbonise the industry.”