Mitsui E&S DU has received an order for two 7X62DF-S2.0 engines from the domestic shipyard, being the first order for these engines which are described as the next generation of LNG-fuelled two-stroke engines.

The engines will be installed in car carriers that will be able to transport 7000 vehicles, with the first scheduled to be completed in April 2025.

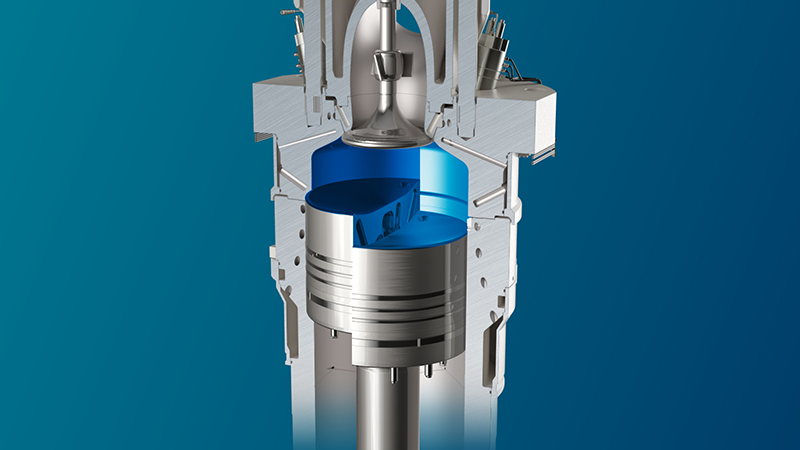

The X62DF-S2.0 series of engines has shown that its fuel consumption in gas mode is 3.7 g/kWh (R1 point) better than the conventional X62DF series engines, even while being lighter and more compact. The engine will be equipped with a Variable Compression Ratio (VCR) mechanism that achieves an excellent specific fuel consumption. The VCR mechanism improves specific fuel consumption. The VCR mechanism improves specific fuel consumption by about 3% in the gas mode or about 6% in the diesel mode by optimising the compression ratio according to the engine’s output and the properties of the LNG fuel, depending on operational conditions such as operation load. It will contribute greatly to the reduction of fuel expenses and CO2 emissions during ship operation.

Mitsui E&S DU jointly developed the VCR mechanism with Winterthur Gas & Diesel (WinGD). The VCR mechanism has been gradually accepted around the world as Mitsui E&S DU has received orders for four engines equipped with the VCR mechanism including the most recent orders. Mitsui E&S DU has received offers for the purchase of over 30 engines with the mechanism from clients in South Korea. The engines in the latest order will be equipped with the on-engine iCER system, a modification to the system intelligently controlling the engine through exhaust recirculation (iCER) that drastically reduces methane slip. Combining the X-DF low-pressure gas injection system with iCER and the VCR mechanism achieves a greenhouse gas (GHG) emissions reduction equal to the high-pressure gas injection DF engine.