Cruise ships can generate thousands of tonnes of wet waste daily, consisting of food waste from restaurants, galleys and bio-sludge from wastewater treatment, and Evac has addressed the question of dealing with this waste in an environmentally-responsible way.

Such waste is regulated by the IMO, and can be discharged into the sea in some areas; however such discharge is questionable and may be stopped where there is increasing emphasis on environmental accountability. Food waste and bio-sludge start to decompose quickly with the possibility of creating a source of harmful gases and diseases. As the size of cruise ships increases, so does the volume of waste that needs to be handled and stored safely. Troublesome storing and landing combined with large quantities makes on board treatment an attractive option.

Against this background, marine clean-tech solution provider Evac has developed a new method for wet waste handling that comes closer to answering customers’ needs. Conventional systems, typically consume large amounts of steam energy for drying the wet waste. In the past, steam was generally available as a side product from main engines, but times have changed.

Mats Riska, senior technical manager, Evac, said: “When cruise itineraries are optimised and the energy efficiency of the main engines is increased, additional steam is not readily available. Therefore, steam needs to be made in boilers resulting in direct diesel consumption.”

Another problem with the conventional dryer system is that the residual waste is the same – just with less water and thus a smaller total volume, meaning that landing the material is still strictly controlled and expensive. Other options include burning the waste after drying in an incinerator or pyrolysis plant. Both methods have limitations related to where and when the burning can be done, as well as generating significant CO2 emissions.

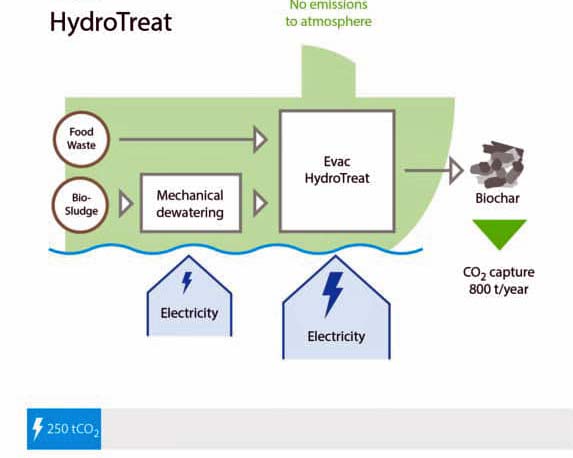

Evac’s new system, HydroTreat, is water-based, meaning that drying is not required. The solid output is sterilised and transformed so it can be treated as normal waste when landing, with nothing discharged into the sea or to the atmosphere. It is said to consume a fraction of the energy, saving on CO2 emissions. The difference is even greater if carbon capture is considered.

HydroTreat is based on a process called ‘hydrothermal carbonisation’ (HTC). Organic material with a high water content is fed into a thermal reactor, where it is exposed to high temperature and pressure. Under these conditions, the material breaks down into carbon molecules, forming a char-like material that is known as ‘hydrochar’, or more commonly as ‘biochar’. The biochar is then extracted through heat exchangers that cool it down and use the released energy to heat up the next batch of waste to be processed. This way most of the energy is retained within the HTC process, maximising system efficiency. The cooled biochar can be dried with a mechanical drier, leaving two streams: reject water that is treated in the vessel’s wastewater treatment system and dry, solid biochar.

Lasse Kapanen, Product Line Manager, Evac, said: “It is a form of carbon capture and the end material could be used for soil improvement, even fertiliser. We are seeing a great deal of potential with the material. Even if these possibilities are not utilised, it can be treated as general waste which is easy to dispose of at a port.”