According to Dutch ship designer Conoship, redox flow batteries (RFB) are already widespread in stationary energy reserve applications, but in the maritime industry their potential remains largely unexplored.

Research by Conoship Naval Engineer Piet Visser suggests that use of RFBs on board short-sea operating vessels coincides with Conoship’s view that full– or part-electric propulsion is a crucial element for reaching the IMO 2050 sustainability goals.

According to Visser, unlike conventional battery systems, RFBs store energy in a liquid electrolyte and release it through electrochemical reactions. The major advantage, compared to traditional batteries, is their energy efficiency, long cycle life, and scalability. Additionally, RFBs do not run the risk of combusting like lithium batteries, providing a major onboard safety boost.

At the core of an RFB is an electrochemical cell divided into two chambers: one positive and one negative, separated by a membrane. The electrolyte, which contains active chemical species, is pumped through these chambers, where energy is stored or released based on the reaction taking place. The choice of electrolyte is crucial, as it determines the battery’s energy density, efficiency, and overall feasibility for marine applications.

Visser’s research looked at a vanadium-based electrolyte using hydrochloric acid (HCl) as a solvent, which was selected due to its high energy density of 43 Wh/l (27 Wh/kg) and stable electrochemical properties. Vanadium redox flow batteries (VRFBs) are particularly attractive because they enable full charge-discharge reversibility, have a long lifespan, and are considered safer than conventional lithium-ion batteries due to their non-flammable nature.

The study focused on the feasibility of implementing RFB technology onboard ships, identifying key challenges such as system integration, operational risks, and safety requirements. A risk-based design approach was used to assess potential hazards, including electrolyte leakage, membrane failures, and material corrosion. To mitigate these risks, design measures such as compartmentalised storage, reinforced piping, and automated leak detection were evaluated to ensure safe and reliable operation at sea.

While the research confirms the technical viability of RFBs for maritime use, further refinement is needed to optimize efficiency and scalability. These findings will provide a foundation for future development, paving the way for broader discussions on how this technology can contribute to sustainable shipping solutions.

The use of RFBs in the maritime industry has the following implications:

- Specialised chemistry expertise is essential for handling electrolytes safely and optimising system performance.

- Industry collaboration is needed to develop maritime RFB applications. The Digital & Green Maritime Coalition can help connect the right partners.

- Retrofitting potential is high, especially for Conoship’s CIP-series, which is designed for future fuel adaptability.

- Further system design is required to refine integration, safety measures, and efficiency for real-world applications.

- Scalability & Modular Design – RFBs have the potential to be modular, allowing ships to scale energy storage based on operational needs. This could be particularly useful for short-sea vessels with varying energy demands.

- Port Infrastructure & Charging – Unlike conventional fuels, RFB electrolyte refuelling and management systems need to be developed at ports. Collaboration with port authorities could accelerate adoption.

- Integration with Hybrid Systems – RFBs could work alongside other energy sources (e.g. methanol, wind, battery-assisted propulsion), making them part of a broader hybrid maritime energy strategy.

Challenges and limitations of RFBs for ships include:

- Implementing RFBs onboard ships presents key challenges, particularly in integrating storage tanks, pumps and piping while ensuring safety and reliability. The corrosive nature of the electrolyte demands strict containment measures to prevent leaks and maintain operational safety.

- RFBs also require significant storage volume, making them less suitable for vessels with tight space constraints. While setup costs are high, their long lifespan and cycle stability offer long-term value.

Currently, RFBs are most viable for short-sea vessels – an area where Conoship specialises. However, further design work is needed before large-scale adoption becomes feasible. While RFBs have yet to be adopted in shipping, their long lifespan, scalability, and safety advantages can potentially make them a compelling option. Conoship is actively exploring how RFB technology can be integrated into its designs, particularly for future-fuel-ready vessels like the CIP-series, and is looking for partners in energy storage, shipbuilding, and regulation to develop practical applications for RFBs at sea.

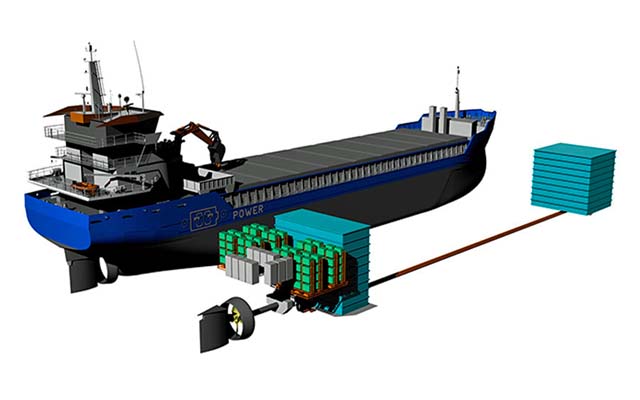

Image: Conoship alternative fuel shortsea vessel proposal (source: Conoship)