Norwegian propulsion company Brunvoll says that efficient machinery with CP propellers, a reduction gearbox with PTO/PTI, and control systems may be considered as the optimum system configuration for vessels with a versatile operational profile.

The reduction gearbox is often overlooked and referred to as a commodity in the propulsion line. In fact, this invaluable unit can be the heart in the propulsion configuration ensuring high flexibility from multiple power units. An efficient propulsion system including reduction gearbox with PTO/PTI opens the doors for all present and future energy sources, whether it is a combustion engine or an electric motor or both connected to the gearbox in the configuration.

Brunvoll’s hybrid PTI/PTO system allows for the highest energy efficiency provided the right energy sources are selected to serve the range of operational conditions varying from lying idle, or sailing in silent zero emission mode, to the need for full power in heavy operations at sea. In PTO-mode the shaft generator is serving energy from the main engines to hotel load or other consumers via the gearbox.

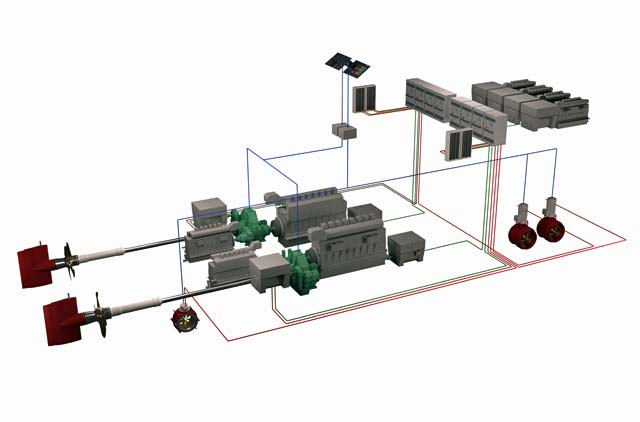

A configuration comprising a twin screw propulsion system (as pictured) with two propellers with ICP (Integrated Costa Propulsion) connected to twin-in single-out gearboxes with in total four combustion engines, two electric motors and two generators, along with batteries and gensets, allows for high flexibility with multiple operation modes and redundancy.

One of the hot topics in shipping is how to improve vessel efficiency to meet the tough requirements of IMO’s CII ratings. Many measures are relevant, and on the technical and operational side an energy efficient propulsion system will reduce the annual energy consumption and thereby improve the CII score.

For vessels in the short sea segment, an electric and hybrid propulsion system can offer the most efficient and reliable propulsion. A propulsion system with a gearbox is optimised to the operation profile of the vessel with the alternative power sources. Adding a reduction gearbox to the propulsion configuration allows use of standard electric motors which gives a cost-effective solution with less weight to the system setup.

In wind-powered propulsion configurations the power can vary significantly based on the weather conditions. Such systems often involve hybrid setups, where multiple power sources are utilised, and a reduction gearbox and controllable pitch propeller maintain optimal performance. For vessels that have a pure sailing condition in part of the operational profile, the CP propeller can be designed for generating energy in water milling or harvesting mode. The generated energy is then transferred to energy storage devices via the gearbox’s PTO system.

A two-speed gearbox and CP-propeller in a hybrid setup with a combustion engine and PTO/PTI for generator/electric motor can provide a fuel-efficient and flexible system. Brunvol says its range of propulsion systems with gearboxes varies from single mode transmission systems to advanced systems customised for vessels with a high number of operation modes. The two-speed gearbox has proven to be a fuel-efficient system, simply by optimising the power and propeller rpm to the main operation conditions.